Home » Products » Gantry Crane » Single Girder Gantry Crane

Single Girder Gantry Crane

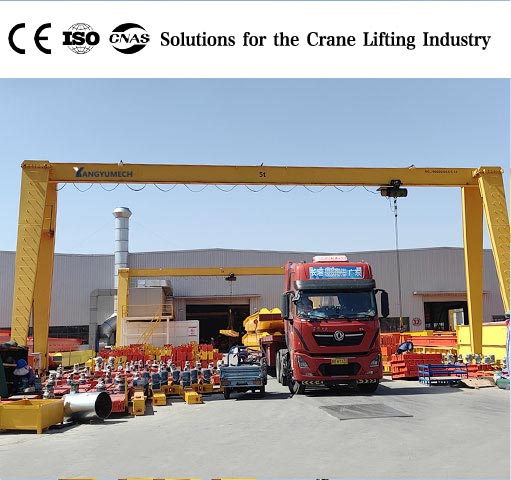

Single girder gantry crane is a common type of gantry crane used indoors or outdoors, and it is also an ideal solution for light duty and medium duty material handling. Yangyumech can offer different type design of single girder gantry crane like box girder, truss girder, L shape girder, with low headroom hoist, standard room (monorail) hoist to meet a range of applications. Our products have the characteristics of compact design, light weight, low noise, easy installation, and maintenance.

• Capacity: 0.3t-36t; Span length: 4-35m

• Lifting height: 6m, 9m, 12m, etc.

• Raged voltage: 220V~690V, 50-60Hz, 3ph AC

• Customized: YES

Description

Single Girder Gantry Crane

Work environment temperature: -25℃~+40℃, relative humidity ≤85%. Crane control mode: Pendant control / Wireless remote control / Cabin control. Reference Price Range: $6000-30000/set

MH type electric hoist gantry crane is designed and manufactured in accordance with national and industry standards such as GB/T3811-2008 “Crane Design Specification” and JB/T5663-2008 “Electric Hoist Gantry Crane”. It is a workshop lifting equipment, which uses CD MD electric wire rope hoist or an electric chain hoist as the lifting mechanism. It can be used indoors and outdoors, such as the docks, freight yards, warehouses, and construction sites.

The single-girder gantry crane is mainly composed of a steel structure gantry, a crane traveling mechanism, an electric hoist, and an electric control system. Normally, single girder gantry cranes are most widely used and often in open storage yards. Considering the high quality, we ensure the gantry cranes price we offer is not the lowest but the most reasonable.

Box-type gantry crane: The box-type gantry crane is a box-type structure with the main beam structure, which has the advantages of high speed and high efficiency. The fixed working environment of the site.

Rubber-tyred gantry crane: Product introduction: The tire-traveling gantry crane is a kind of gantry crane that uses tires instead of steel wheels to travel on the basis of the box gantry crane. It has the advantages of high speed, high efficiency and no need to pave the subgrade.

Truss gantry crane: The truss gantry crane is a truss structure with a main beam structure. It has the advantages of advanced structure, reasonable mechanical performance, portability, high rigidity, simple operation, convenient use, safety and reliability, and convenient disassembly.

As one of the experienced gantry crane manufacturers, we can produce different specifications of the crane.

Features

1. Follows the international design code, like FEM, CMAA, EN ISO.

2. Can equip with low headroom hoist or standard room hoist.

3. The girder is compact, low self-weight, and welded by S355 material, the welding specification follows ISO 15614, AWS D14.1. Deflection can be from 1/700 ~ 1/1000. MT or PT is requested for fillet welding, and UT is requested for joint welding.

4. The end carriage can be hollow shaft or open gear type design, the wheel is made by alloy steel with proper heat treatment.

5. Branding gear motor with IP55, F insulation class, IE3 Energy

6. Efficiency, over-heat protection, manual release bar, and electro-magnetic brake feature. The motor is controlled by inverter for smooth running.

7. The control panel design follow IEC standard, and is installed inside IP55 enclosure with socket for easy Installation.

8. Double line Galvanized C track festoon system with flat cable, one line for hoist power and signal transmission, one line for the pendent control trolley movement.

9. SA2.5 Surface pre-treated by blasting according to ISO8501-1; C3-C5 painting system according to ISO 12944-5

Technical Data

| Rated Load(Kg) | Working Level | Lifting Height | Lifting Speed | Iranversing speed | Traveling Speed | |

|---|---|---|---|---|---|---|

| FEM | ISO | M | M/Min | M/Min | M/Min | |

| 3000 | 1AM-4M | M3-M6 | 6/9/12/15/18 | 0.8/5 | 2~20 | 3~30 |

| 5000 | 1AM-4M | M3-M6 | 6/9/12/15/18 | 0.8/5 | 2~20 | 3~30 |

| 6300 | 1AM-4M | M3-M6 | 6/9/12/15/18 | 0.8/5 | 2~20 | 3~30 |

| 8000 | 1AM-4M | IM3-M6 | 6/9/12/15/18 | 0.8/5 | 2~20 | 3~30 |

| 10000 | 1AM-4M | IM3-M6 | 6/9/12/15/18 | 0.8/5 | 2~20 | 3~30 |

| 12500 | 1AM-3M | M3-M5 | 6/9/12/15/18 | 0.8/5 | 2~20 | 3~30 |

| 16000 | 1AM-3M | M3-M5 | 6/9/12/15/18 | 0.66/4 | 2~20 | 3~30 |

| 20000 | 1AM-3M | M3-M5 | 6/9/12/15/18 | 0.66/4 | 2~20 | 3~30 |

| 25000 | 1AM-3M | M3-M5 | 6/9/12/15/18 | 0.8/3.2 | 2~20 | 3~30 |

| 32000 | 1AM-3M | M3-M5 | 6/9/12/15/18 | 0.8/3.2 | 2~20 | 3~30 |

Purchasing Process

FAQs About Choosing the Right Gantry Crane and Supplier

In order to obtain accurate quotes for custom overhead cranes, providing the following core information will greatly improve efficiency:

1. Key specifications: including rated lifting weight (tons), span (i.e., track spacing, meters), and lifting height (meters), which is the basis of the design.

2. Use environment and working conditions: Explain the conditions of the installation site (such as indoor/outdoor, temperature, humidity) and work level (busy level), which determines the material selection and configuration level of the structure.

3. Specific configuration requirements: clarify the drive mode (such as frequency conversion control), brand preferences for electrical components, safety devices (such as overload limiters, anti-collision systems), and whether special functions such as remote control are required.

4. Installation and service: confirm the on-site power supply conditions (voltage, frequency), installation conditions, and specific expectations for delivery time, installation and commissioning, and after-sales service.

The more detailed the information provided, the more accurate and reliable the solutions and quotations obtained.

1. Span and lifting capacity: this is the foundation.The larger the span and the higher the rated lifting weight, the material and design costs of the main beam and structure will increase significantly, and the higher the price.

2. Working level and frequency of use: The working level (A1-A8) represents the busy level and load status of the crane.Cranes with frequent and heavy-duty use require more durable motors, gearboxes and structural parts, and the cost is naturally higher than that of lightweight and occasionally used equipment.

3. Structure and configuration: The double beam is more complex and stable than the single beam structure, and the price is higher.At the same time, the lifting height, operating speed, motor brand, control system (ordinary vs frequency conversion), and the level of safety devices (such as anti-swing, load monitoring) all directly affect the final quotation.

4. Degree of customization and brand service: completely standard models have lower costs.The customized design based on the workshop environment (such as explosion-proof and high temperature), special processes (such as metallurgical special), brand added value, and after-sales guarantee system will all be reflected in the price.

In simple terms, when buying a bridge crane, it is necessary to consider “how much, how frequently, what environment and what configuration”, which determine its core value and price.

Which crane to choose mainly depends on your specific needs. You can quickly judge from the following four core aspects:

-Single-beam bridge crane: it is suitable for conventional workshops with light and medium loads (usually ≤20 tons), medium span, and low frequency of use. It is the most economical and versatile choice.

-Double-girder bridge crane: used for heavy-duty, long-span, or high-work-level occasions (such as frequent hoisting, metallurgy, heavy-duty assembly). Its stability, durability, and safety are higher, but the cost is also increased accordingly.

-Free vertical crane (cantilever/column type): suitable for fixed working points and working conditions with limited rotation range, such as beside machine tools, maintenance areas, or production line stations, it can efficiently use corner space and be installed flexibly.

-Grab crane: It is specially used for the handling, loading, and unloading of bulk materials (such as grain, coal, sand, and gravel). The only reason to choose it is that you need to deal with such unpackaged loose materials.

In simple terms, you can filter according to this logic:

First, according to the lifting weight and span, choose between a single beam and a double beam.

If the scope of operation is highly concentrated and the space is limited, consider a free vertical.

If the handling object is bulk material, it points directly to the grab type.

Delivery times largely depend on whether the crane is standard or customized. Based on our experience, standard single-girder and double-girder cranes can be produced more quickly, while cranes with special spans, duty ratings, or environmental requirements naturally require additional engineering design time.

For each quotation, we provide an estimated production and delivery schedule based on your configuration and destination. Throughout the manufacturing process, our team maintains communication with the customer to ensure no unexpected issues arise before shipment.

Compared with many suppliers, Yangyumech mainly reflects the two differentiated advantages of high customization flexibility and clear international compliance when providing bridge cranes.

On the one hand, we focus on in-depth customized services. According to your specific needs, we can provide fully customized solutions on core parameters such as rated load capacity, span, and lifting height, and accept personalized requirements. This means that what you get is not a standard product, but exclusive equipment that accurately matches the working conditions of your workshop.

On the other hand, we attach importance to international standards and quality certification. Our products clearly meet the requirements of international certifications such as CE, which ensures that their safety and reliability can meet the mainstream standards of the international market, and provides you with additional quality confidence guarantees. Combined with our direct supply capabilities as a powerful factory, we can achieve better comprehensive value for you while obtaining compliant and customized products.

Hot Products

Single Girder Gantry Crane

- Lifting height: 6m, 9m, 12m, etc.

- Raged voltage: 220V~690V

LD Single Beam Bridge Crane

- Lifting Height: 5-50m

- Capacity: 1t-40t

European Standard Electric Hoist

- Working Class(FEM): 1Am-4m

- Lifting Height (m): 6/9 12/18